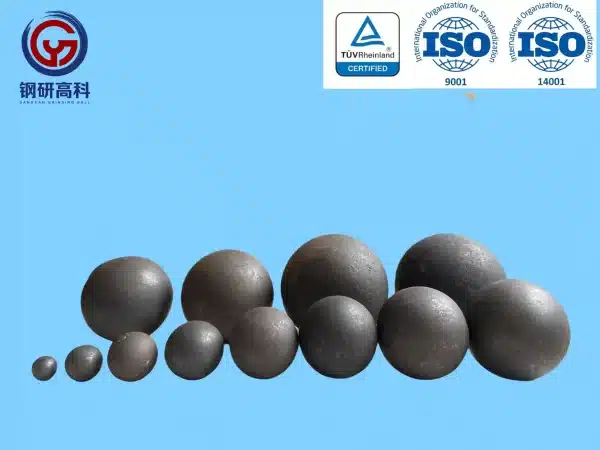

We offer two main types of grinding balls:

grinding steel ball are high-efficiency grinding media specially engineered for use in ball mills. They are widely applied across multiple industries including mining, cement manufacturing, thermal power plants, and chemical processing.

1. Forged Steel Balls

-

Made from premium alloy steel and processed through precision forging.

-

Features:

1) High Hardness: surface hardness of forged and rolling ball is to 60-67HRC and volume hardness is to 60-65HRC

2) High Impact Toughness: impact toughness is more than 12 J/cm2

3) Low Broken Rate: the broken rate is not higher than 1%

4) Wear-resistant: the wear rate of grinding media is 80-500g/ton -

Chemical composition and Hardness:

(1)Alloy Grinding Ball

Hardness: HRC50-55

Chemical Elements:

C:0.37-0.55 Si:0.17-0.37 Mn:0.50-0.80 S:≤0.035 P:≤0.035 Cr:≤0.25 Ni:≤0.25

(2)Forged Manganese Alloy Grinding Steel ball (60Mn,65Mn,75Mn)

Hardness: HRC60-65

Chemical Elements:

C:0.42-0.70 Si:0.17-0.37 Mn:0.70-1.20 S:≤0.030 P:≤0.030 Cr:≤0.25 Ni:≤0.25

(3)B2 Forged Grinding Steel Ball

Hardness: HRC60-68

Chemical Elements:

C:0.72-0.85 Si:0.17-0.37 Mn:0.70-0.9 S:≤0.030 P:≤0.030 Cr:0.4-0.6

(4)B3 Forged Grinding Steel Ball

Hardness: HRC60-68 C:0.58-0.66 Si:1.6-1.9 Mn:0.65-0.8 S:≤0.030 P:≤0.030 Cr:0.7-0.9 -

Best for:

-

Wet milling operations, especially in mining and power generation sectors requiring long-term durability under intense conditions.

2. Cast Steel Balls

-

Manufactured using high-temperature casting techniques.

-

Size: Diameter 17-150mm

Product Category:

(1)Low Chromium Casting Grinding Ball

Hardness: HRC45-55

Chemical Elements:

C:2.2-2.5 Si:≤1.2 Mn:0.5-2.0 Cr:1.0-5.0 S:≤0.05 P:≤0.05(2)Middle Chromium Casting Grinding Ball

Hardness: HRC52-60

C:2.2-3.3 Si:≤1.2 Mn:0.5-2.0 Cr:5.0-9.0 S:≤0.05 P:≤0.05(3)High Chromium Casting Grinding Ball

Hardness: HRC60-65

C:1.6-3.3 Si:≤1.0 Mn:0.5-2.5 Cr:10-16 Mo:0.3-1.5 Cu:0.2-1 S:≤0.01 P:≤0.01(4)Super High Chromium Casting Grinding Steel Ball

Hardness: HRC60-65

Chemical Elements:

C:2.0-3.3 Si:≤1.0 Mn:0.5-2.5 Cr:≥17 Mo:1.0-2.0 Cu:0.8-1.5 S:≤0.01 P:≤0.01

-

Features:

-

Cost-effective production

-

Excellent heat resistance

-

-

Best for: Dry milling processes, particularly in cement plants and high-temperature environments.

Applications

-

Mining industry: Grinding metal ores and tailings

-

Cement production: Clinker and raw material grinding

-

Power plants: Grinding fly ash and slag

-

Chemical industry: Pulverizing materials for reaction processes

Why Choose Our Grinding Steel Balls?

-

Compliant with international standards (ISO9001、ISO14001、TUV)

-

Customizable sizes and hardness

-

Strict quality control

- Bulk order support and fast delivery

Ready to Improve Your Grinding Efficiency?

Contact us today to learn more about our high-quality grinding balls and get a personalized quote for your needs.

Click here to get start!⬇