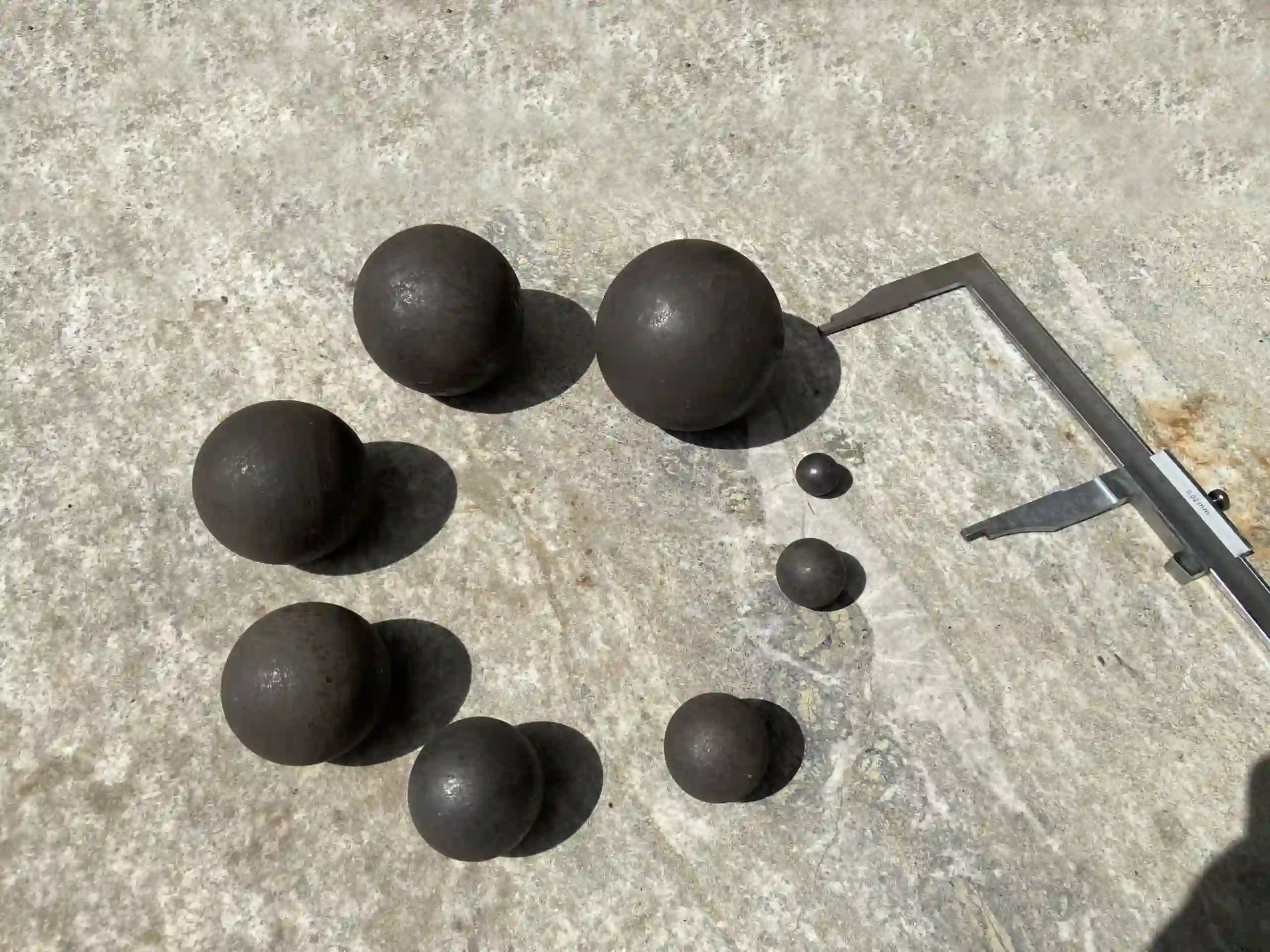

At Shandong Gangyan Grinding Ball Co., Ltd., we know that the wear resistance of forged steel grinding balls depends not only on surface hardness, but also on carbon content and internal microstructure. Our R&D team is committed to delivering the most wear-resistant solutions to help our customers reduce costs and increase efficiency. Long-term research and testing have led us to the following important insights:

1. Same Hardness ≠ Same Wear Resistance

Steel balls with different carbon contents, when tempered at the same temperature, can achieve the same surface hardness (e.g., HRC48–49). However, their actual wear resistance may differ significantly. Even when both types have a tempered martensitic structure, the difference in carbon content alone can result in one ball lasting much longer than the other. This clearly shows that carbon content and microstructure are crucial—not only for achieving hardness, but for determining how long the grinding ball will truly last in real-world applications.

2. Microstructure Matters More Than Hardness

When comparing pearlitic and martensitic steel balls, both tempered at the same temperature and having the same hardness (HRC30), the wear performance still differs. The layered pearlite structure is less wear-resistant than martensite, even at identical hardness levels. This means that wear resistance depends more on the internal structure than on surface hardness alone.

3. More Carbon Isn’t Always Better

High-carbon steel balls (e.g., martensite + 23% pearlite/bainite) and lower-carbon balls (pure martensite), both at HRC58.5, still show a clear difference in wear resistance. The presence of non-wear-resistant pearlite and bainite in high-carbon balls actually causes faster wear compared to fully martensitic, lower-carbon balls.

4. Proper Heat Treatment Improves Low-Carbon Balls

High-carbon pearlitic balls with a hardness of HRC29 can improve to HRC41.7 after quenching and tempering—along with significantly better wear resistance. Similarly, low-carbon steel balls can achieve excellent performance when heat-treated correctly, showing that carbon content alone doesn’t tell the whole story.

What Does This Mean for You?

-

Hardness alone is not enough. Balls with the same hardness can perform very differently in wear resistance.

-

Microstructure is key to durability and grinding efficiency.

-

Carbon content must be optimized and matched with the right heat treatment process.

At Shandong Gangyan Grinding Ball Co., Ltd., we engineer every ball to achieve the ideal combination of carbon content, hardness, and microstructure, ensuring exceptional wear resistance in real working conditions.

📩 Contact us today to learn how our forged grinding balls can improve your mill performance and lower your operating costs.